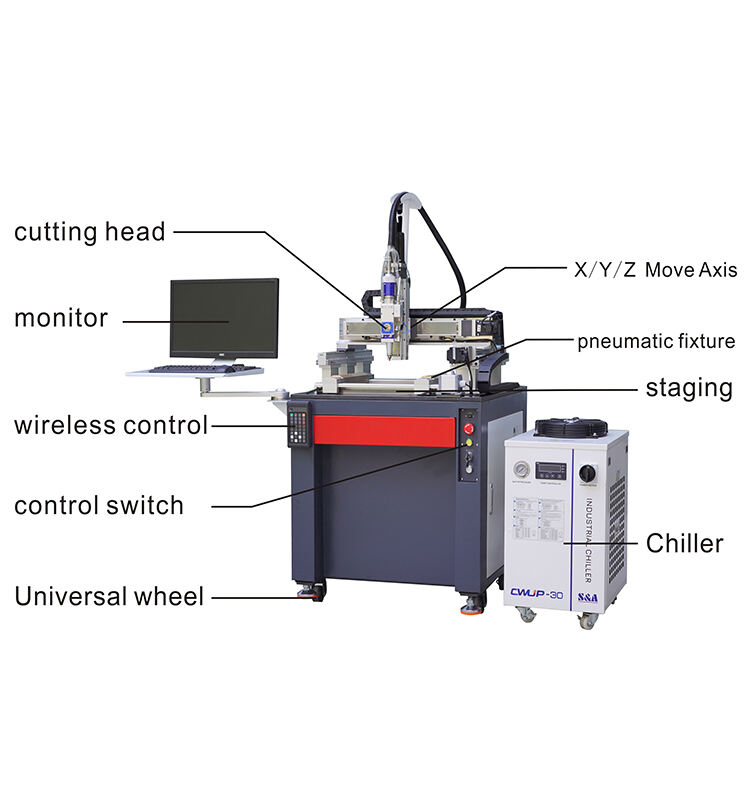

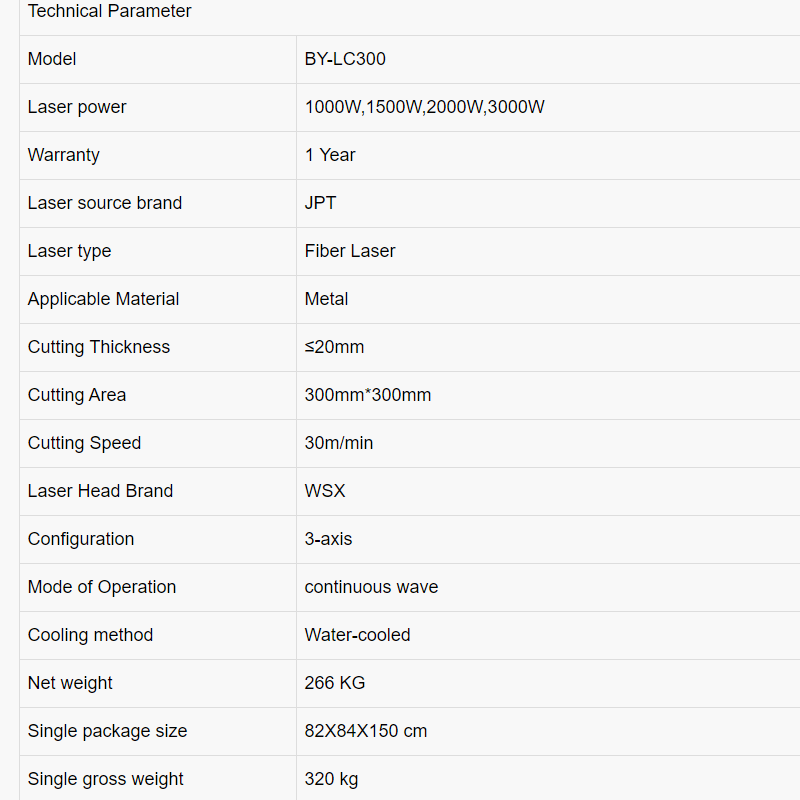

Model: BY-LC300

Metal laser cutting machine plays an irreplaceable role in modern manufacturing industry with its advantages of high precision, high efficiency and wide applicability of materials, and is an important tool for realising precision manufacturing and improving production efficiency.

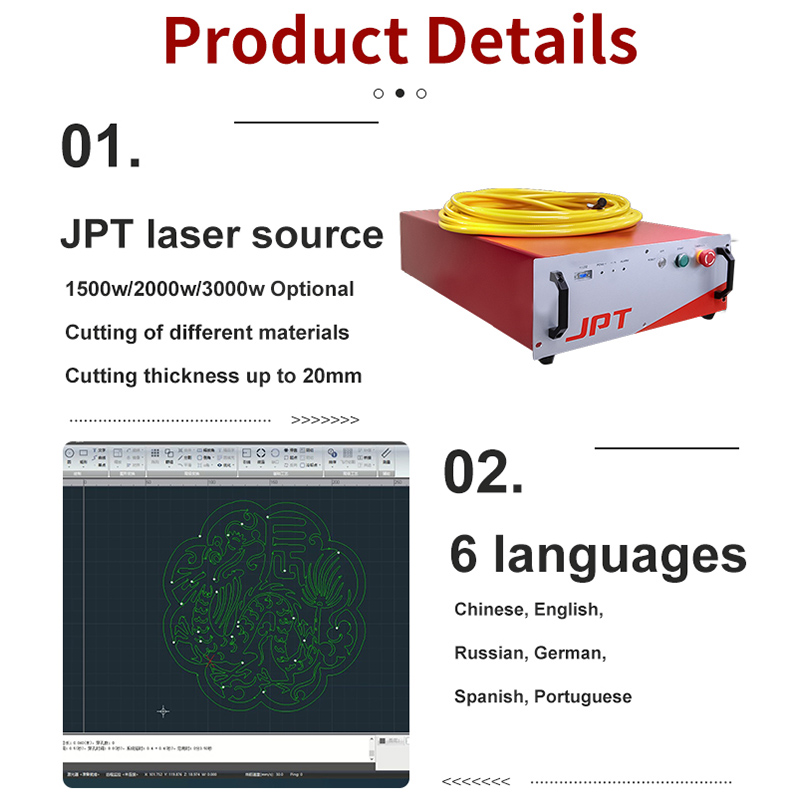

This Small Fiber Laser Cutting Machine is a cutting machine newly developed by BY Laser. It is widely used in carbon steel plate cutting, stainless steel plate cutting, aluminum plate cutting, brass cutting, purple copper cutting and so on.

Model: BY-LC300

Metal laser cutting machine plays an irreplaceable role in the modern manufacturing industry with its advantages of high precision, high efficiency and wide applicability of materials, and is an important tool for realising precision manufacturing and improving production efficiency.

This Small Fiber Laser Cutting Machine is a cutting machine newly developed by BY Laser. It is widely used in carbon steel plate cutting, stainless steel plate cutting, aluminum plate cutting, brass cutting, purple copper cutting, and so on.

Main Advantages:

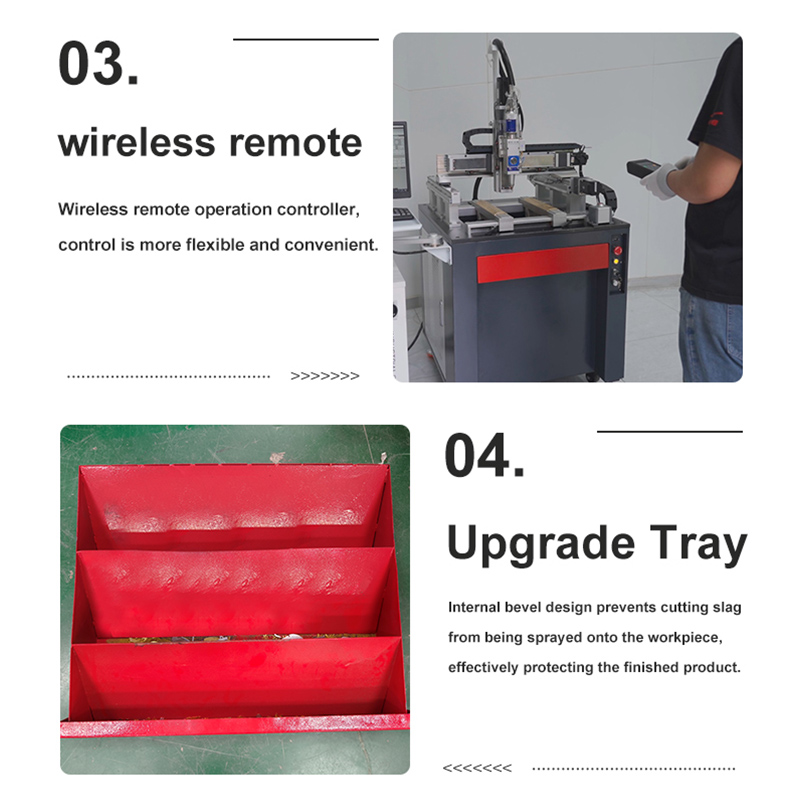

1. High efficiency: laser cutting speed, high degree of automation, can significantly improve production efficiency.

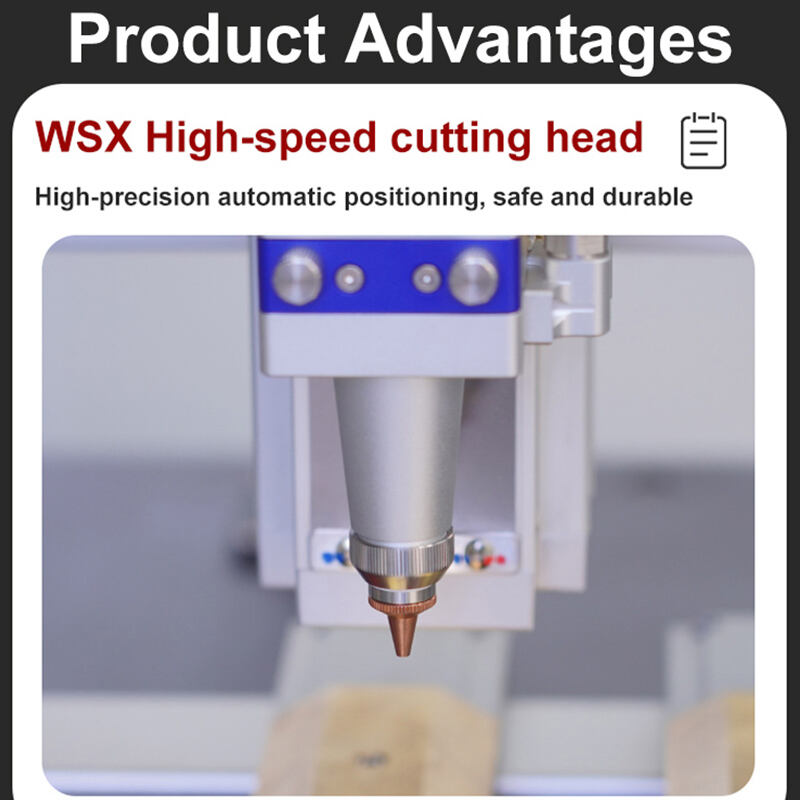

2. High precision: the laser beam is extremely fine after focusing, with small heat-affected area, which ensures flat and smooth cutting edges and high dimensional accuracy.

3. Non-contact processing: laser cutting is non-contact processing, will not cause mechanical damage to the material, reduce material waste.

4. Flexibility: it is suitable for cutting all kinds of complex shapes, not limited by shape, and suitable for personalised customisation.

5. Wide material applicability: it can cut a variety of metal and non-metal materials, including high hardness and high brittleness materials.

6. Environmental protection: the laser cutting process produces less smoke and dust, low noise, and has little impact on the environment.

7. Low maintenance cost: laser cutting machine maintenance is relatively simple, long-term running costs are low.

Application Fields

1. Advertising signage production: stainless steel logo, signage cutting

2. Sheet metal processing: including the cutting of various metal materials, such as stainless steel, carbon steel, aluminium, etc.

3. Jewellery industry: to achieve a very high degree of precision, so that the complex pattern cutting possible; and to avoid scratches or deformation that may occur in the traditional cutting, to maintain the integrity of the material and aesthetics

4. Kitchen utensils: cutting of stainless steel kitchen utensils, such as knives, cutlery, kitchen equipment, etc.

5. Metal crafts industry: can achieve personalized customization, such as hollowing screens, metal brackets, etc.

6. Spring sheet manufacturing: precision cutting of spring sheets to meet the needs of precision machinery and electronics industry