×

×

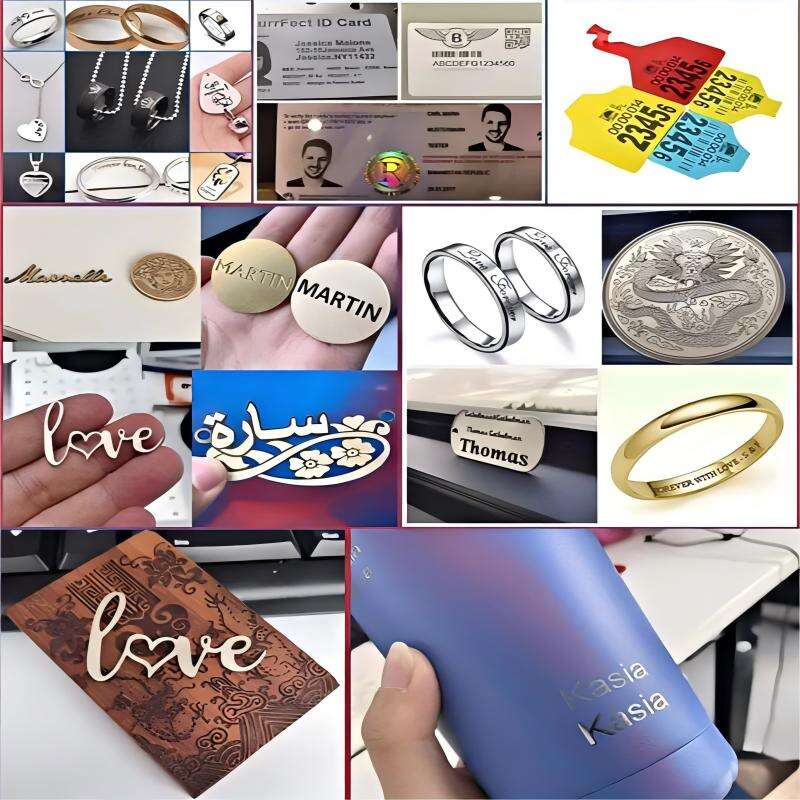

With its high precision, high efficiency, and wide range of applications, desktop fiber laser marking machines play an important role in modern manufacturing industry and are essential tools for improving product quality and productivity. Whether it is fine electronic component marking or personalised jewellery customisation, fibre laser marking machine can provide reliable support.

Features:

1. Maintenance-free and long service life:

Our system uses a laser diode as the pump source and is designed with a fully sealed optical path. As a result, it is extremely reliable, with an average runtime of over 100,000 hours and virtually no maintenance.

2. Fast processing speeds:

Utilizing our cutting-edge technology, processing speeds are 5-10 times faster than traditional laser marking machines. This ensures that you get your marking job done efficiently and quickly.

3. Excellent machine quality

The parts used in the machine are all famous brands—for example, JPT, Raycus laser source, ZBTK, Sino-Galvo, and so on.

4. 0 consumables

The whole machine does not need to replace any accessories within 5-10 years (under good maintenance conditions).

5. Convenient and easy to use

Integrated air cooling system, no water cooler required. No need to replace or clean lenses, etc.

6. EACAD Control (Support Lightburn), Roating engraving, Support auto-focus

Application

1. Electronic industry

-PCB board marking: marking barcode, 2D code and other information on printed circuit boards for easy tracking and management.

-Chip marking: marking model number, batch number and other information on integrated circuit chips.

2. Automotive Manufacturing

-Parts marking: Used to mark serial number, production date, batch and other information on auto parts to ensure product traceability.

-Anti-counterfeiting marking: Marking anti-counterfeiting codes on automotive parts to improve product security.

3. Medical Devices

-Medical device marking: Marking necessary information on medical devices such as surgical instruments and implants to ensure product traceability and safety.

4. Jewellery

-Personalisation: Marking of brand logo, production number or personalised text on metal jewellery such as rings and necklaces.

-Gemstone engraving: engraving patterns or text on diamonds, emeralds and other gemstones to increase beauty and uniqueness.

5. Metal products

-Tool marking: Mark trademarks, model numbers and other information on metal tools such as hardware tools and moulds.

-Equipment nameplate: mark nameplate information on mechanical equipment, such as equipment model, manufacturer, etc.

6. Artwork and souvenirs

-Metal artwork: fine engraving on metal artwork to enhance the value and beauty of the artwork.

-Personalised souvenirs: marking on souvenirs with customized text or patterns.