Due to the short wavelength of the UV laser and the small focused spot, high precision marking can be performed on very small areas. The heat it generates is very limited and hardly causes thermal deformation or thermal damage to the material. Theref...

Due to the short wavelength of the UV laser and the small focused spot, high precision marking can be performed on very small areas. The heat it generates is very limited and hardly causes thermal deformation or thermal damage to the material. Therefore, for some materials that are susceptible to thermal deformation or damage (such as plastic, glass, etc.), UV laser marking machines are very suitable.

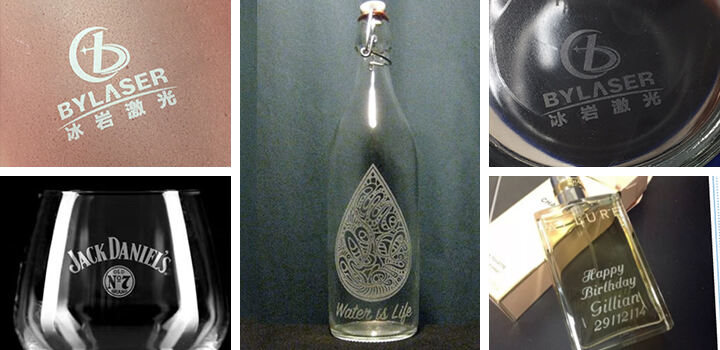

Application cases of UV laser marking machine in glass:

1. Glass bottle marking

-Application Scenario: Marking of brand logo, production date, batch number and other information on glass bottles.

-Advantage: UV laser marking machine can form a clear and lasting mark on the surface of glass bottles, and will not cause damage to the bottles. This marking method is more environmentally friendly than traditional labelling or inkjet printing, and the marking is not easy to wear or fall off.

2. Glassware engraving

-Application Scenario: Personalised engraving on glassware such as wine glasses, vases, crystal crafts, etc., such as lettering and patterns.

-Advantage: UV laser marking machine can achieve high-precision engraving, even complex patterns can be finely rendered. In addition, this engraving method will not cause cracks or damage to the glassware, maintaining the beauty and integrity of the vessel.

3. Optical Glass Marking

-Application Scenario: Marking on optical glass, lenses, filters and other optical components, such as serial number, model number and other information.

-Advantage: UV laser marking machine is capable of marking optical glass with high precision and high contrast, ensuring that the marking does not affect the light transmission performance of the optical components. The clarity and durability of the marking helps in the management and tracking of the optical components.

4. Automotive glass marking

-Application Scenario: Marking of production information, certification marks, etc. on automotive windscreen, side window glass and other components.

-Advantage: UV laser marking machine can form clear and durable markings on automotive glass without affecting the transparency and strength of the glass. This marking method improves the traceability and safety of automotive glass.

5. Architectural glass marking

-Application Scenario: Marking on architectural glass for safety marking, production information and so on.

-Advantage: UV laser marking machine is able to make non-contact marking on building glass without causing scratches or damages to the glass surface. The marking is clear and long-lasting, which helps in building safety management and maintenance.

6. Glass Artwork Engraving - Application Scenario: Fine engraving on glass artwork, such as abstract patterns, landscape paintings and so on. -Advantage: UV laser marking machine can achieve very fine engraving effect, even the tiny details can be perfectly presented. This kind of engraving not only enhances the value of the artwork, but also increases its ornamental and artistic qualities.

7. Glass Packaging Bottles

-Application Scenario: Marking of brand logo, pattern, etc. on high-grade glass packaging bottles such as perfume bottles, cosmetic bottles and so on.

-Advantage: UV laser marking machine can form delicate and clear markings on the surface of glass bottles to enhance the product grade and brand recognition. The durability and beauty of the marking also make the package more attractive.

8. Laboratory glassware-

Application Scenario: Marking of capacity scale, experiment number, etc. on the glassware used in the laboratory.

-Advantage: The UV laser marking machine is able to mark the glassware with high precision, ensuring the clarity and accuracy of the marking. The marking will not wear out due to frequent use, which improves the reliability of experimental data.

9. Glass Lenses

-Application Scenario: Marking on eyeglass lenses with degree marking and production information.

Advantage: UV laser marking machine is able to make non-contact marking on the lenses without affecting the optical properties of the lenses. The marking is clear and long-lasting, which is convenient for the management of glasses production and sales.

10. Glass Screen

-Application Scenario: Marking of serial numbers, production information, etc. on glass screens of electronic devices such as smart phones and tablet PCs.

-Advantage: UV laser marking machine is able to mark the glass screen with high precision without affecting the display effect of the screen. The marking is clear and long-lasting, which improves product traceability and safety.