×

×

In the realm of heavy engineering, where the demands for structural integrity and durability are paramount, the utilization of laser welding machines has revolutionized the industry. One such example is a prominent heavy engineering firm that has emb...

In the realm of heavy engineering, where the demands for structural integrity and durability are paramount, the utilization of laser welding machines has revolutionized the industry. One such example is a prominent heavy engineering firm that has embraced laser welding technology to enhance the structural integrity of its products.

Prior to adopting laser welding, the firm relied heavily on traditional welding methods, which often led to inconsistencies in weld quality and structural integrity. With the introduction of a laser welding machine, the firm was able to achieve precise and reliable welds, significantly improving the overall structural strength of its products.

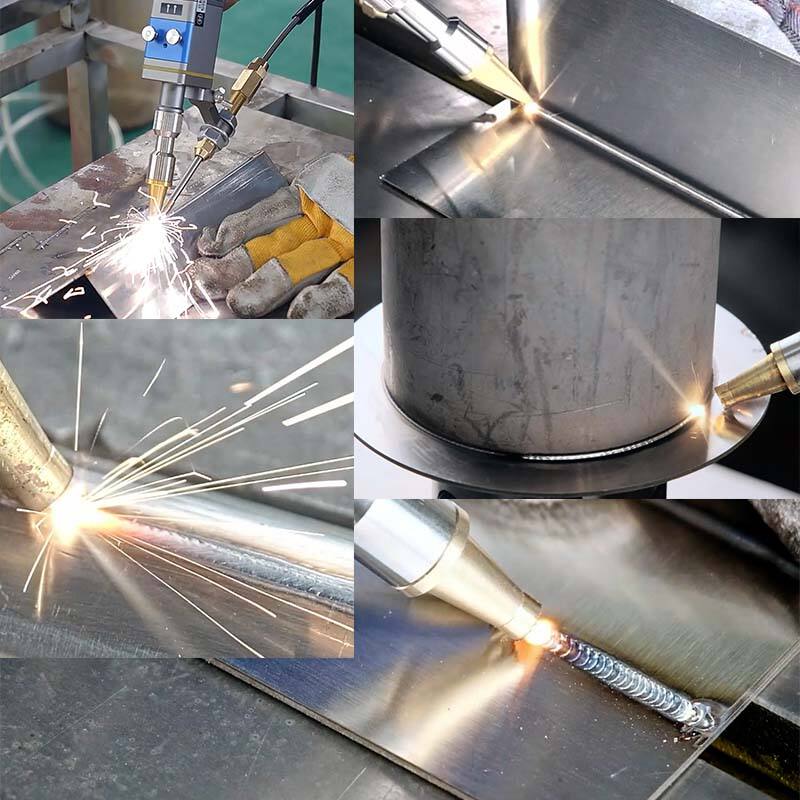

The laser welding machine works by utilizing high-energy laser beams to create localized heat, which melts the adjacent metal surfaces to form a strong and durable bond. The precision of the laser beam allows for extremely accurate welds, minimizing the potential for imperfections or defects.

In the heavy engineering firm's case, the laser welding machine was used to weld large-scale components and structures. The firm found that the laser welding process resulted in welds that were stronger, more uniform, and less prone to cracking or distortion compared to traditional welding methods.

Furthermore, the laser welding machine's ability to weld dissimilar metals and alloys was a significant advantage for the firm. This flexibility allowed the firm to create complex structures using a variety of materials, further enhancing the structural integrity of its products.

The introduction of the laser welding machine also led to improvements in production efficiency. The laser welding process is faster and more automated than traditional welding methods, reducing the need for manual labor and minimizing production downtime.

In summary, the laser welding machine has been a transformative technology for the heavy engineering firm. By enabling precise and reliable welds, the laser welding machine has significantly improved the structural integrity of the firm's products, while also enhancing production efficiency. As the industry continues to evolve, laser welding machines are poised to play an increasingly important role in ensuring the structural integrity of heavy engineering products.